About the Department

Excavation Department of Western Coalfields Limited ensures the availability&reliabilityof Heavy Earth Moving Machinery (HEMM) to support Open-Cast Mining operations and achieve departmental production targets. The department manages equipment planning, procurement, commissioning, maintenance, and refurbishment, supported by advanced tools and workshops. Using Condition-Based Monitoring (CBM) and IoT-enabled systems, it enhances predictive maintenance, operational efficiency, and resource optimization. With a focus on training, safety, and environmental compliance, the Excavation Department supports sustainable and high-performance mining operations by keeping critical machinery ready for use. Summary of Major Equipment Population in WCL as of 01.01.2026 are Electric Rope Shovel-7 no. , Hydraulic Excavator -65 no., Rear Dumper - 304 no., Dozer-147 no. , Rotary Blast Hole Drill-66 no., Water Sprinkler-50 no. & Motor Grader -31 no.

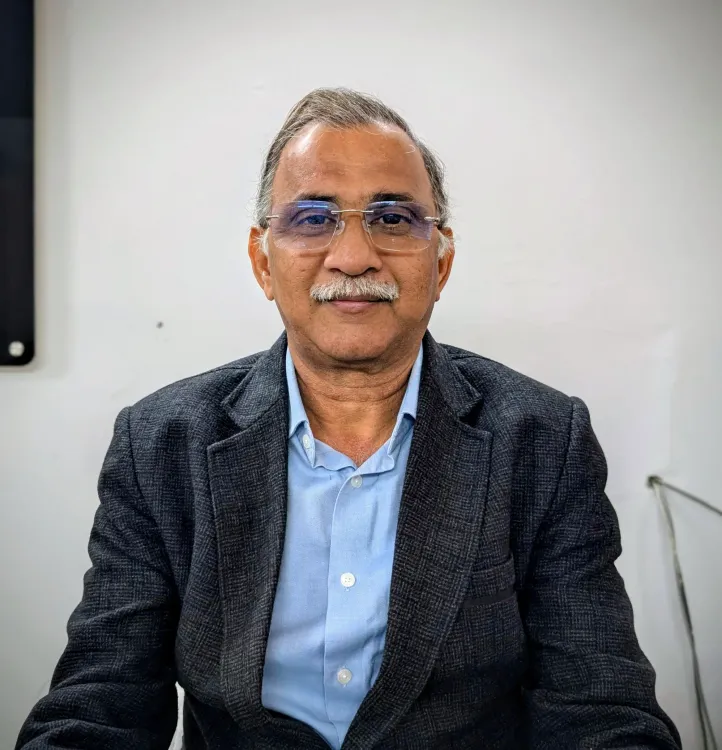

Head of Department

Shri Raghava Venkata Rao Pasumarty

General Manager (Excavation)

Shri Raghava Venkata Rao Pasumarty, General Manager (Excavation), assumed charge as Head of the Excavation Department on 01.10.2025. He holds a B.Sc. degree in Electrical Engineering from University College of Engineering, Burla, Sambalpur University (1988) and joined Coal India Limited on 14.12.1989, beginning his career with Northern Coalfields Limited (NCL). With over three decades of experience in Open Cast Mining, Shri Pasumarty has served in major NCL projects including Jayant and Dudhichua Mines, where he worked in key roles across the Excavation Department. He functioned as Shovel Section In-Charge and Manager (Field Equipment), handling 20 Cu.M capacity Electric Rope Shovels and other high-capacity HEMMs, with responsibilities encompassing equipment performance, maintenance, and productivity enhancement. On promotion, he was transferred to Western Coalfields Limited (WCL) in May 2017 and posted at the Mungoli Project, Wani Area, where he was In-Charge of Dragline, handling critical excavation equipment and ensuring operational reliability. He later served in Nagpur Area from June 2020 and was entrusted with the responsibilities of Staff Officer (Excavation), Nagpur Area in August 2023, involving planning, monitoring, and coordination of various functions of Excavation Department, Nagpur Area. In June 2025, he joined Central Workshop (CWS), Tadali as General Manager, a state-of-the-art centralized workshop facility of WCL, where he was associated with major overhauls, refurbishment, condition-based maintenance practices, and reliability assurance of heavy mining equipment. Thereafter, he was transferred to WCL Headquarters in October 2025 as Head of the Excavation Department. A seasoned excavation professional, Shri Pasumarty possesses extensive hands-on expertise in Draglines, 20 Cu.M electric rope shovels, and other high-capacity Open Cast Mining equipment, with strong focus on equipment lifecycle management, reliability, safety, cost optimization, and productivity enhancement.

Key Roles & Functions

1. Equipment Planning & Management

Planning, budgeting, and procurement of HEMM, Spares, Critical Assemblies and Plant & Machinery to ensure optimal availability and operational efficiency.

2. Performance & Lifecycle Management

Erection, Commissioning and Maintenance of HEMM. Monitoring equipment performance, utilization, and lifecycle to maximize productivity, reduce downtime, and manage survey-off/disposal in line with CIL Survey off Norms.

3. Maintenance, Workshops & Refurbishment

Coordinating Unit workshops and the Central Workshop, Tadali for major overhauls, repairs, and refurbishment of engines, transmissions, and heavy Sub-assemblies.

4. IoT & Technology Upgradation

Deploying fuel-efficient, environmentally compliant HEMM with real-time diagnostics, predictive maintenance, and monitoring systems to optimize productivity and reliability.

5. Safety & Risk Management

Implementing robust safety systems in HEMM, emergency preparedness, and alert mechanisms to protect personnel, equipment, and operations.

6. Training & Skill Development

Conducting structured programs and simulator-based training for operators and maintenance personnel to enhance competence and operational excellence.

7. Resource Optimization & Sustainability

Monitoring fuel, payload, and consumables to improve efficiency, reduce losses, and support environmentally responsible mining practices.

8. Environmental Compliance & Quality Systems

Ensuring adherence to environmental regulations, ISO and quality standards, and effective use of ERP/digital systems for transparent and sustainable operations.